In the dazzling world of modern industry, a powerful transformation is underway, one that promises to redefine the very essence of manufacturing as we know it.

We are living in the era of Industry 4.0 and Smart Manufacturing, a technological revolution that is reshaping production processes, elevating efficiency to new heights, and propelling businesses into the future.

Buckle up as we take a deep dive into this captivating phenomenon and discover how it’s poised to transform our world.

What is Industry 4.0 and Smart Manufacturing?

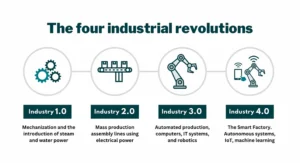

Before we dive into the exciting world of Industry 4.0 and Smart Manufacturing, let’s demystify these buzzwords. Industry 4.0 refers to the fourth industrial revolution, marked by the integration of digital technologies into manufacturing processes.

It’s all about interconnecting machines, products, and people through the Internet of Things (IoT), Artificial Intelligence (AI), Big Data, and more. The ultimate goal? To create smarter, more agile, and more efficient factories.

Smart Manufacturing, on the other hand, is the practical realization of Industry 4.0. It’s about harnessing the power of data and technology to optimize every aspect of manufacturing, from production lines to supply chains. Smart Manufacturing empowers businesses to make data-driven decisions, improve product quality, reduce downtime, and enhance the overall customer experience.

Now that we’ve set the stage, let’s explore the birth of Industry 4.0 and how it’s poised to change the manufacturing landscape forever.

The Birth of Industry 4.0

A Digital Renaissance: Industry 4.0 emerged as a response to the increasing complexity and demands of global manufacturing. In the late 2000s, the concept gained momentum as businesses sought ways to stay competitive in an ever-evolving landscape.

The Rise of IoT: IoT paved the way for Industry 4.0 by connecting machines and devices like never before. By 2020, an astounding 31 billion IoT devices were in use worldwide, and this number is projected to grow to 75 billion by 2025. These devices enable real-time data collection and analysis, enhancing productivity and predictive maintenance.

Big Data Dominance: Industry 4.0 thrives on data, and the numbers are staggering. By 2020, we were generating an estimated 2.5 quintillion bytes of data each day. Manufacturers are now harnessing this wealth of information to optimize their processes, reduce waste, and meet customer demands more effectively.

The AI Revolution: Artificial Intelligence has infiltrated every corner of manufacturing, from automated quality control to predictive maintenance. In fact, it’s estimated that AI in manufacturing will be worth $16.7 billion by 2026. Machine learning algorithms are continuously improving production efficiency and enabling adaptive manufacturing processes.

Human-Machine Collaboration: In the Industry 4.0 era, humans and machines work hand in hand. Collaborative robots (cobots) are becoming commonplace on factory floors, increasing productivity and safety. By 2025, the global market for collaborative robots is projected to reach $11.6 billion.

Now that we’ve explored the roots of Industry 4.0, let’s delve deeper into its real-world applications and how it’s transforming manufacturing.

The Industry 4.0 Revolution in Action

Predictive Maintenance: Traditional maintenance approaches are a thing of the past. Industry 4.0 allows machines to monitor their own health in real time, predicting when maintenance is needed. This reduces downtime by up to 45% and lowers maintenance costs by 10-40%.

Enhanced Quality Control: Smart Manufacturing introduces quality control processes that are more precise than ever before. With AI-driven inspections, defects can be identified at a microscopic level, reducing defective products by up to 90%.

Agile Production: Industry 4.0 enables agile manufacturing, allowing for rapid adjustments in production schedules and product customization. This agility is vital in a market where consumer demands are constantly changing.

Supply Chain Optimization: Smart Manufacturing isn’t limited to the factory floor; it extends to the entire supply chain. Businesses can track the movement of materials and products in real-time, reducing waste and ensuring timely deliveries.

Sustainable Practices: The Industry 4.0 revolution isn’t just about efficiency; it’s about sustainability too. Smart Manufacturing helps reduce energy consumption, minimize waste, and lower the environmental impact of production processes.

Mass Customization: In the age of Industry 4.0, it’s possible to produce customized products on a mass scale. This personalization increases customer satisfaction and opens up new revenue streams.

The Bottom Line: A Revolution with Results

If you’re wondering whether Industry 4.0 and Smart Manufacturing are all talks and no action, the numbers speak for themselves:

-

Boosted Productivity: Manufacturers adopting Industry 4.0 technologies report up to a 20% increase in productivity.

-

Reduced Costs: Operational costs can be slashed by up to 30% through improved efficiency and reduced waste.

-

Enhanced Quality: With AI-powered quality control, manufacturers achieve a 50% reduction in defects.

-

Faster Time to Market: Smart Manufacturing reduces product development time by up to 25%.

-

Increased Profitability: Manufacturers using Industry 4.0 technologies see a 10-15% increase in profitability.

Improved Sustainability: Eco-conscious practices driven by Industry 4.0 result in a 15% reduction in environmental impact.

The Future Is Now

Industry 4.0 and Smart Manufacturing are not just trends; they are the new standards of modern manufacturing. Those who embrace these transformative technologies are not only staying competitive but thriving in an ever-evolving global marketplace.

As the revolution continues, we can expect even more groundbreaking innovations. From 3D printing and blockchain integration to augmented reality in training and maintenance, the possibilities are limitless. The only constant in this era of Industry 4.0 is change, and those who adapt are the ones who will lead the way.

In conclusion, the marriage of Industry 4.0 and Smart Manufacturing is ushering in a new era of production, one characterized by agility, efficiency, sustainability, and profitability. The numbers don’t lie, and the results are undeniable.

It’s not a question of whether your business should embrace this revolution; it’s a question of how soon you can get on board. Don’t wait until your competition leaves you in the digital dust. Embrace the future of manufacturing today, and watch your business soar to new heights.

With each passing day, Industry 4.0 and Smart Manufacturing are solidifying their place in the manufacturing landscape. The advancements in technology, the incredible potential for cost savings, and the undeniable impact on the bottom line make these concepts impossible to ignore.

Industry 4.0: A Global Phenomenon

Industry 4.0 is not limited to a single region or industry. It’s a global phenomenon that’s redefining how businesses produce, manage, and deliver products. Let’s take a look at how different parts of the world are embracing this revolution.

Europe’s Visionary Approach: Europe has been a pioneer in embracing Industry 4.0. Countries like Germany, known for their precision engineering, have integrated smart manufacturing into their industrial DNA. In fact, the German government launched the “Industrie 4.0” initiative to promote the digitalization of manufacturing.

The Asian Powerhouse: Asia, particularly China, has rapidly adopted Industry 4.0 technologies. China’s “Made in China 2025” initiative focuses on upgrading its manufacturing sector through automation and technology integration. Chinese factories are now among the most advanced in the world.

The American Innovation Hub: The United States, with its tech giants and innovation hubs, is driving Industry 4.0 advancements. Silicon Valley is a hotbed for developing cutting-edge technologies that are transforming manufacturing processes. American manufacturers are increasingly investing in automation and data analytics.

Africa’s Growing Potential: Even in Africa, Industry 4.0 is gaining traction. Countries like South Africa and Kenya are exploring the possibilities of smart manufacturing to boost their industrial sectors. This demonstrates that Industry 4.0 is not just for established industrial giants; it’s a path to economic growth for emerging markets as well.

Industry 4.0 in Your Business

Now that we’ve explored the global impact of Industry 4.0, you may be wondering how to implement these technologies in your own business. Here are some actionable steps to get started:

-

Assess Your Current State: Begin by assessing your current manufacturing processes. Identify areas where efficiency can be improved, where data can provide insights, and where automation can reduce costs.

-

Invest in IoT Infrastructure: Building a robust IoT infrastructure is crucial. This includes sensors, data collection systems, and connectivity solutions that allow machines and devices to communicate seamlessly.

-

Embrace Data Analytics: Invest in data analytics tools and expertise to make sense of the vast amount of data you’ll be collecting. Data-driven decision-making is at the heart of Industry 4.0.

-

Train Your Workforce: Prepare your workforce for the digital transformation. Ensure that your employees have the necessary skills to operate, maintain, and troubleshoot advanced manufacturing systems.

-

Start Small, Scale Fast: Begin with pilot projects to test the waters. Once you’ve seen the benefits, scale up your initiatives across your organization.

-

Collaborate and Innovate: Industry 4.0 is a collaborative effort. Partner with technology providers, research institutions, and industry peers to stay at the forefront of innovation.

-

Monitor and Adapt: Continuously monitor the performance of your smart manufacturing systems and be ready to adapt to changing circumstances and technologies.

The Road Ahead

As we embark on this journey of Industry 4.0 and Smart Manufacturing, the possibilities are limitless. From self-optimizing factories to supply chains that can predict disruptions, the future is bright for businesses that embrace these technologies.

So, whether you’re a small-scale manufacturer or a global industrial giant, the message is clear: the future of manufacturing is here, and it’s smart, efficient, and ready to revolutionize production as we know it.

Don’t just watch from the sidelines; be a part of this transformative wave. Industry 4.0 and Smart Manufacturing are not merely trends – they are the future of how we make things, and the future is now.